M²m³ Protected Surface 494 m²m³ Weight 350kg m³ VolumeTank Final Design 27. Description of the MBBR Moving Bed Biofilm Reactor Process II.

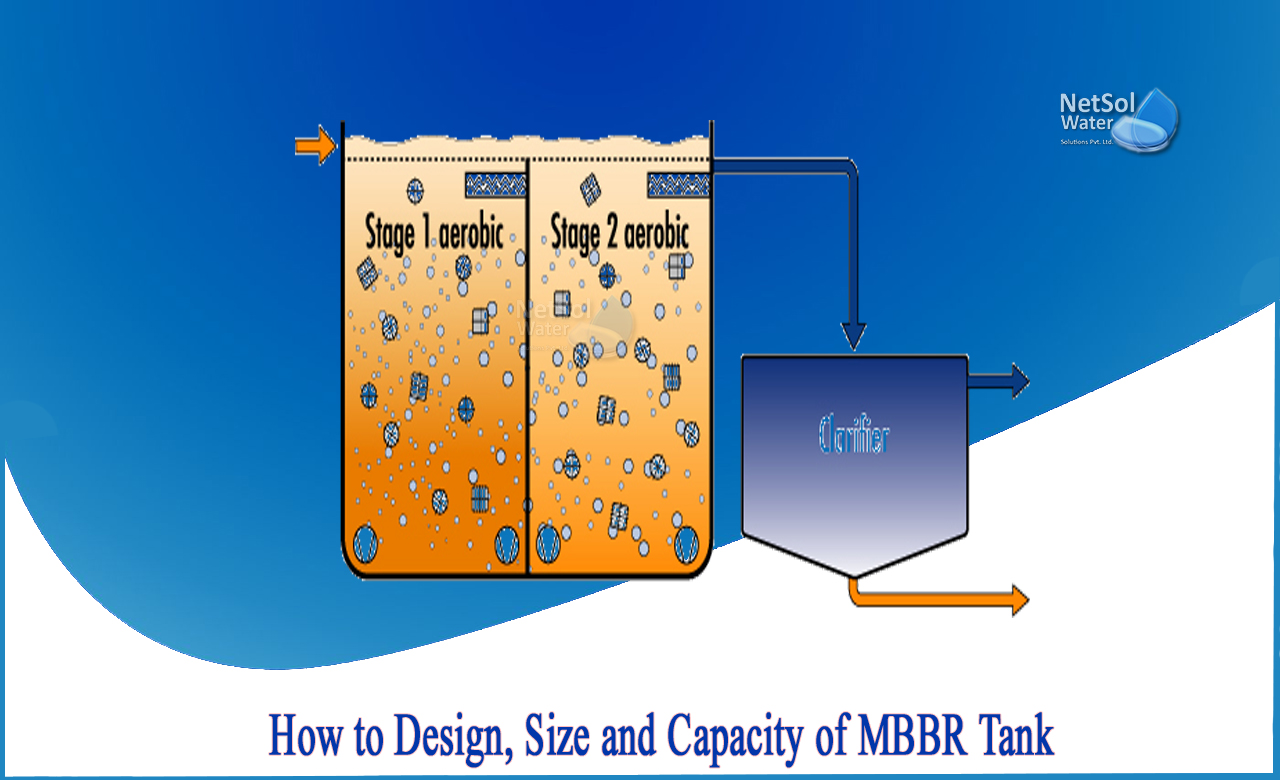

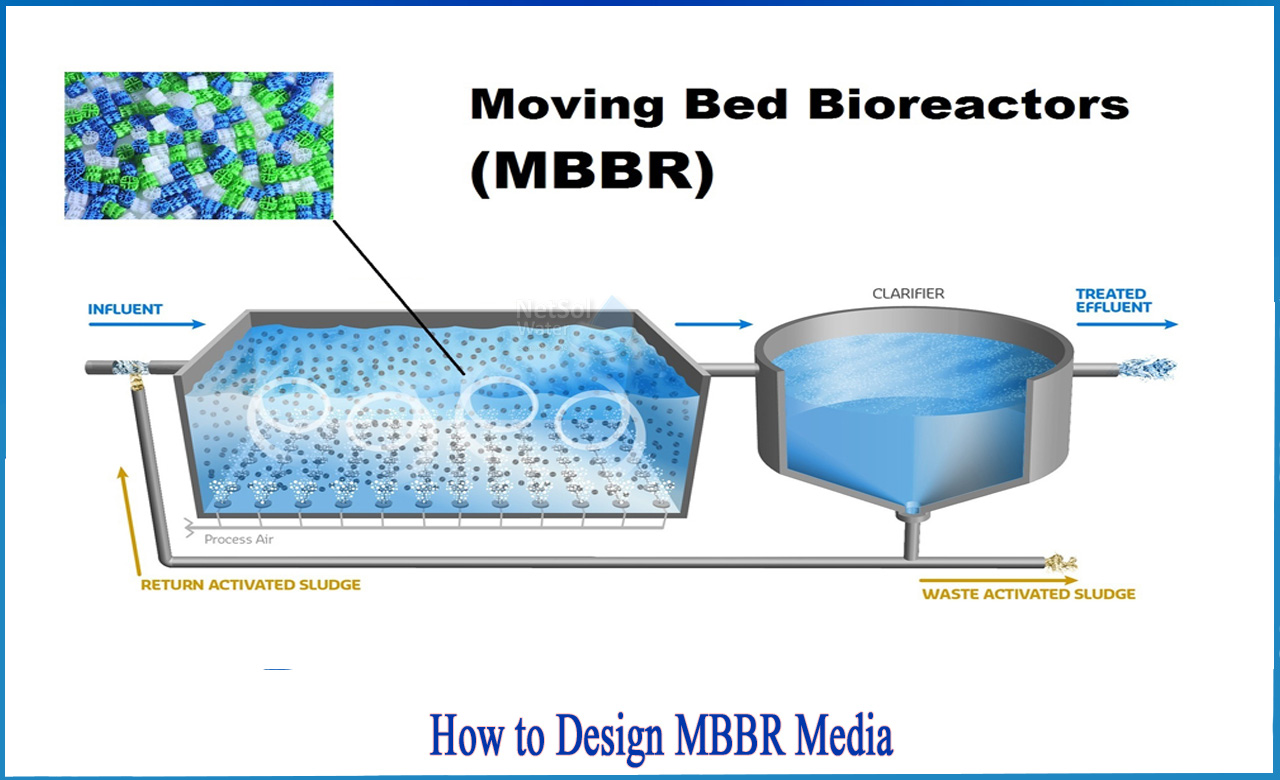

Moving Bed Bioreactors MBBR is wastewater treatment technology in which wastewater is treated biologically by circulating moving media in aerobic and anaerobic activated sludge environments.

. The MBBR is moving bed bio-film reactorThe carrier is composed of a material with a density close to the density of water 1 gcm 3One example is high density polyethylene. Read customer reviews find best sellers. Moving Bed Bio-Film Reactor MBBR.

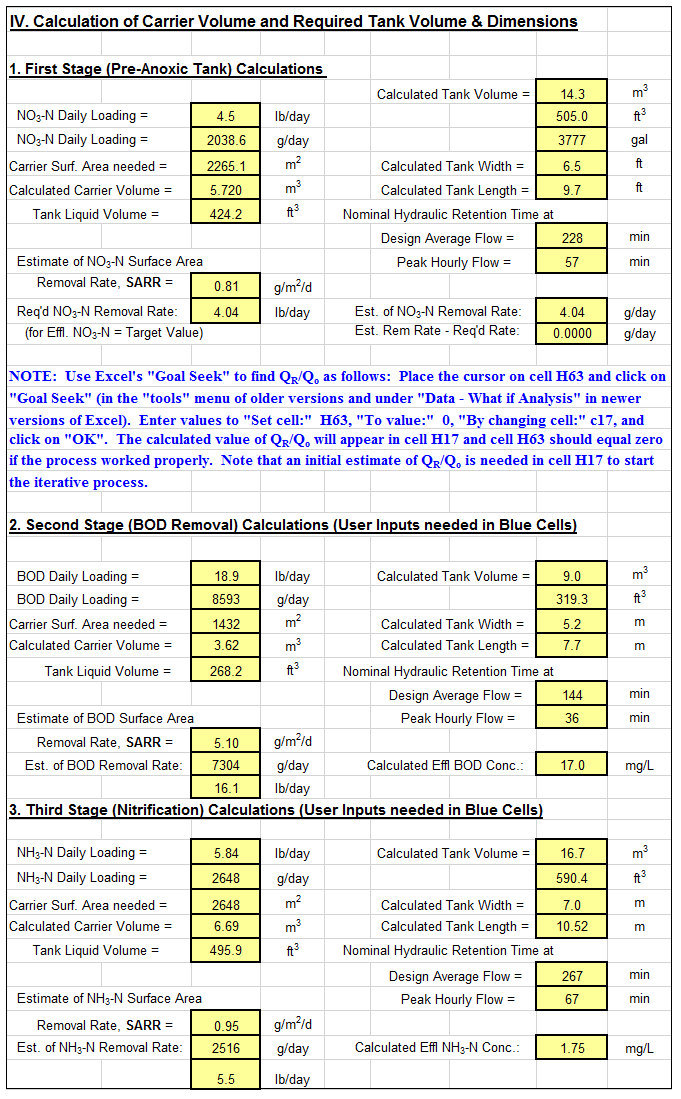

There are two ways to calculate the volume for the MBBR media to Nitrogen revival BOD removal and COD removal MBBR system. Answer 1 of 6. HRT design average reactor liquid volume748Q106 2460 9843074810106 2460 708 min HRTpeak hr.

60 volume of Media to 40 volume of water is the rule of thumb. Say 30l of media needs a 50l of media compartment of the reactor tank with the above ratio holding 20l of water. How to design Size and Capacity of MBBR tank.

Mbbr Tank Design Calculation. Suppose 60 percent media volume is equal to 3 m3 of a typical MBBR tank with a 4-5 hours retention period. About the Moving Bed Biofilm Reactor MBBR wastewater treatment process including background information about the process and a description of the process as well as.

Calculation of Aeration Requirement in MBBR Aeration requirement in wastewater treatment plantThe reference to this video is Metcalf Eddy wastewater eng. I calculated the volume of Tank and Media. General Inputs BOD Daily Loading lbday gday m3 m2 ft3 gal cylindrical rectangular Liquid Depth in Tank Single-Stage Process for BOD Removal Click on green box and then on arrow to Select Tank Shape.

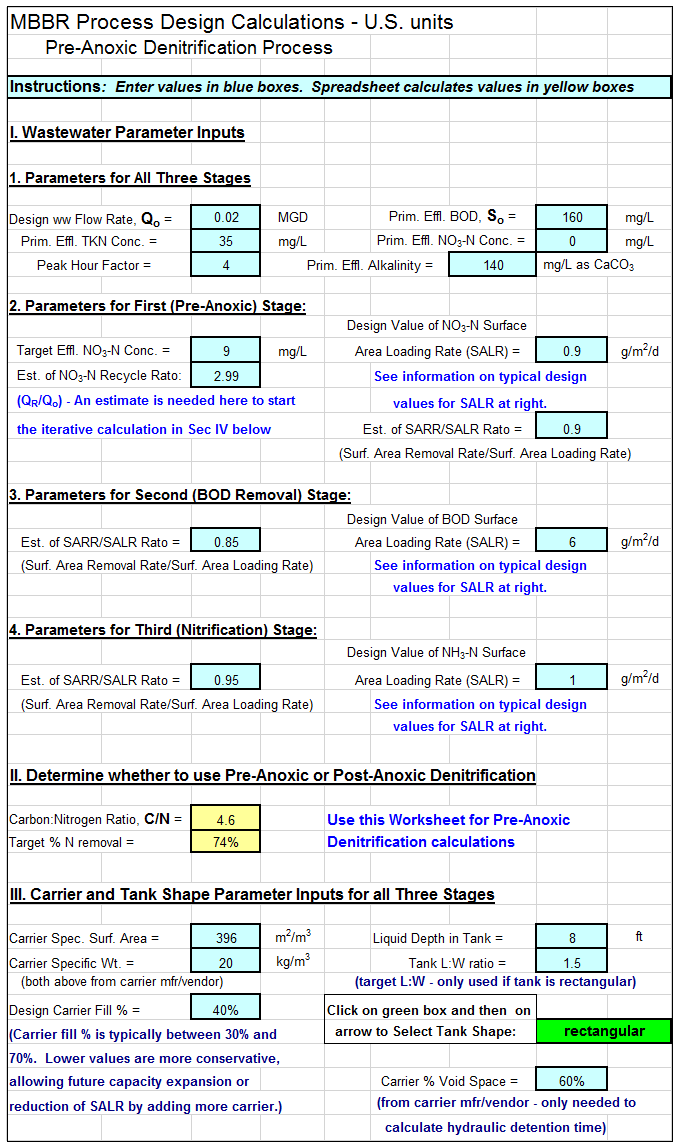

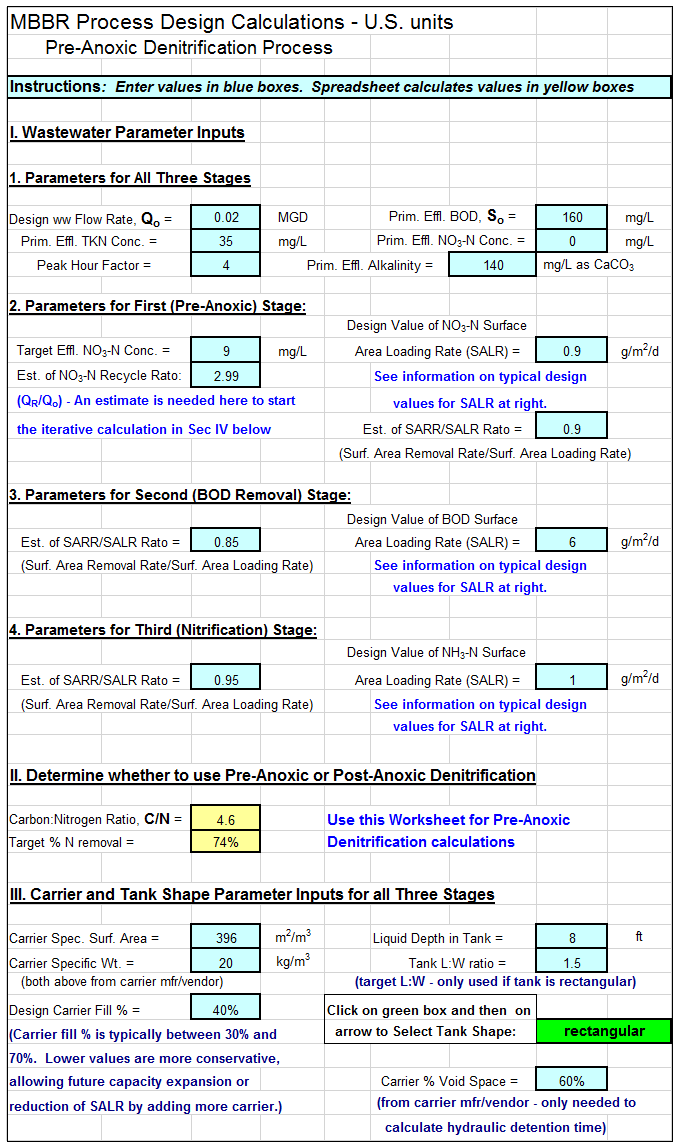

The MBBR is moving bed bio-film reactorThe carrier is composed of a material with a density close to the density of water 1 gcm 3One example is high density polyethylene HDPE which has a. Moving Bed Biofilm Reactor Introduction and designing and planning parameters Mohammad Mehdi Golbini Mofrad MSCs. Be able to make process design calculations for a pre-anoxic denitrification MBBR process including required tank sizes estimated effluent concentrations and alkalinity requirements 3.

One of these biological processes is MBBR or Moving bed bio film reactor. Browse discover thousands of brands. Ad Enjoy low prices on earths biggest selection of books electronics home apparel more.

For any assistance suggestions or feedback. As usual for the common projects we fill about 30 of the Aerotank volume. EQ tank instrumentation to sense and adjust aeration nutrient dosing and pH dosing during peaks Adjust MBBR SALR to account for potential inorganic fouling DAF operation typically preferred Use calamity tank is common MBBR SALR as primary treatment 8-12g BODm2 MBBR SALR as pre-treatment.

The first way is very easy and just for Roughly estimated. Ignoring the water inside the media assuming it to be solid. The Juntai MBBR reactor consists of a tank.

The Juntai MBBR plant can be designed as a stand-alone treatment process or to provide pre-treatment effluent polishing nitrification or nutrient reduction. I design the MBBR plant for wastewater treatment. I design the MBBR plant for wastewater treatment.

Units gm2d m2m3 1. In treatment scheme of wastewater biological processes are also usedOne of these biological processes is MBBR or Moving bed bio film reactor. Design ww Flow Rate Q MBBR Process Design Calculations - US.

This tool is useful for MBBR design calculations. In treatment scheme of wastewater biological processes are also used. The MBBR treatment process is typically used for smaller 10000 gpd flows ammonia polishing and high-strength wastewater pre-treatment.

Topics Covered in this Course I. I calculated the volume of Tank and Media. Single Stage BOD Removal MBBR Process Design Calculations.

The aeration tank will be essentially a completely mixed tank so the process design calculations for the aeration tank can be done using a completely mixed activated. Min Design Average Flow Peak Hourly Flow Tank LW. Technical calculations for the biological treatment plant Alex Tagbo.

Review of papers and literatures. Suppose 60 percent media volume is equal to 3 m3 of a typical MBBR tank with a 4-5 hours retention period. Mbbr tank design calculation If subtlety isnt your matter Opt for anything with a bit more blingFrom words to jewels and perhaps chains theres no Restrict on the 3D factors you are able to attach to the nails so get creative.

The fill rate of MBBR media is 15 to 60.

How To Design Size And Capacity Of Mbbr Tank

Mbbr Wastewater Treatment Design Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Mbbr Nitrification Denitrification Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel

Amazon Com Spreadsheets For Mbbr Process Design Calculations Ebook Bengtson Harlan H Bengtson Harlan Books

Mbbr Nitrification Denitrification Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel

0 comments

Post a Comment